Co-House

Spring 2021 Lithopic Co-House Studio: Professor Dana Cupkova

One of three student projects featured in Dana Cupkova’s participation in the 2022 Tallinn Architecture Biennale

Exterior Render

Can architecture heal soil over time?

Co-House is a cooperative housing project focused on mitigating sick soils and toxic rainwater runoff in the post-industrial Hazelwood neighborhood in Pittsburgh. The design explores water flow with experiences like a public staircase, aqueducts, and step wells.

Due to drastic topography, the neighborhood is split into onion-like layers that radiate out from the Monongahela River. The industrial zone on the river side, the central commercial zone, and the hilltop residential zone are separated by unbuilt areas with steep topography. This design is situated in one such unbuilt zone, replacing a run down public stair between the commercial and residential rings to create a stronger connection through form and program. The site provides a shared house at the top of the site, a daycare in the center, and a business incubator at the base.

This site was chosen for its history as an area for illegal dumping, for the steep topography and risk of landslide, and underused public staircase. These features make this site prone to toxic soil and rain runoff , a challenge addressed through the integration of water filtration, bioswales, gardening step wells, and site shaping to mitigate water flow, features that were designed to help heal the site over time.

Zoomed out plan showing the water flow across the site.

Program layout

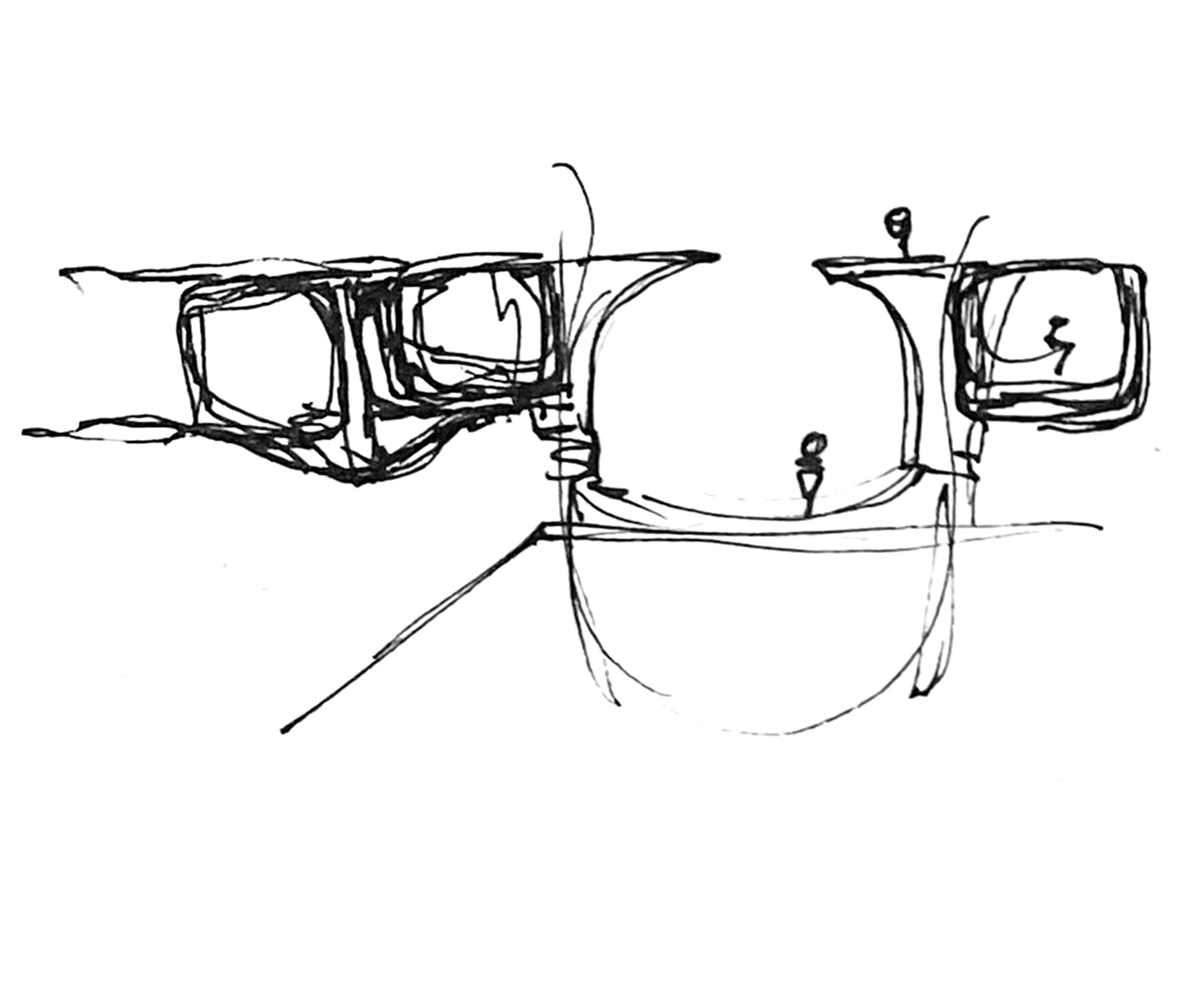

INITIAL SKETCHES

The form was a play in positives and negatives. Wells and the roofs envelope the user on the ground and in the sky. Arches and domes invert that form to carve out the interior space. These positives and negatives form circles of transitioning worlds.

SITE MAPPING

This site in the neighborhood was chosen for the potential harm if left untreated. The possible toxic and sick soils can contaminate the water runoff to the river below, or cause more damage to the forests that cover the area. The site layout was arranged to clean as much of the rain water and soil as possible. Bioswales were formed at the high flow zones, and the natural pits in the landscape became urban gardening dimpled step wells.

generated from optimized form for depth and texture

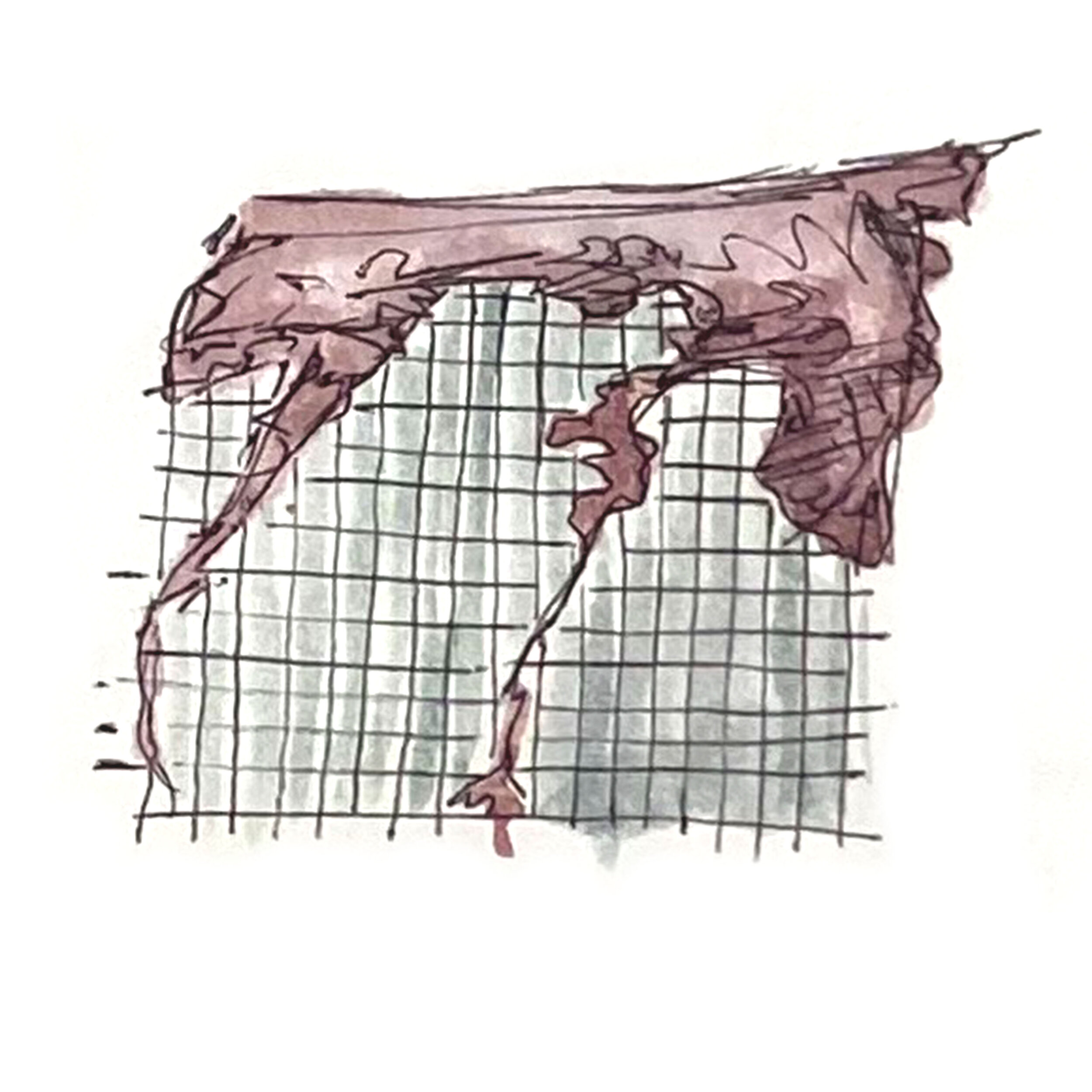

STRUCTURE

The structure was created through shape optimization that minimized the material needed to support the structural load. An asymmetrical arch was optimized to form the fossil-like structure. The load bearing points were set to be on the top of the form, where the users would walk across the arches, and on the sides of the base, where the arches are braced in the ground. The resulting optimized shape was then thickened and hollowed to create space for the filter system to integrate into the structure and to support rain water collection for the urban gardens.

MICRO-TEXTURE

The surface detailing was a part of a feedback loop with the overall form that was meant to host for a living ecosystem on horizontal and vertical surfaces. The texture was used to create the grooves of the stepwells and bioswales as well as the facade and roof design of the houses.

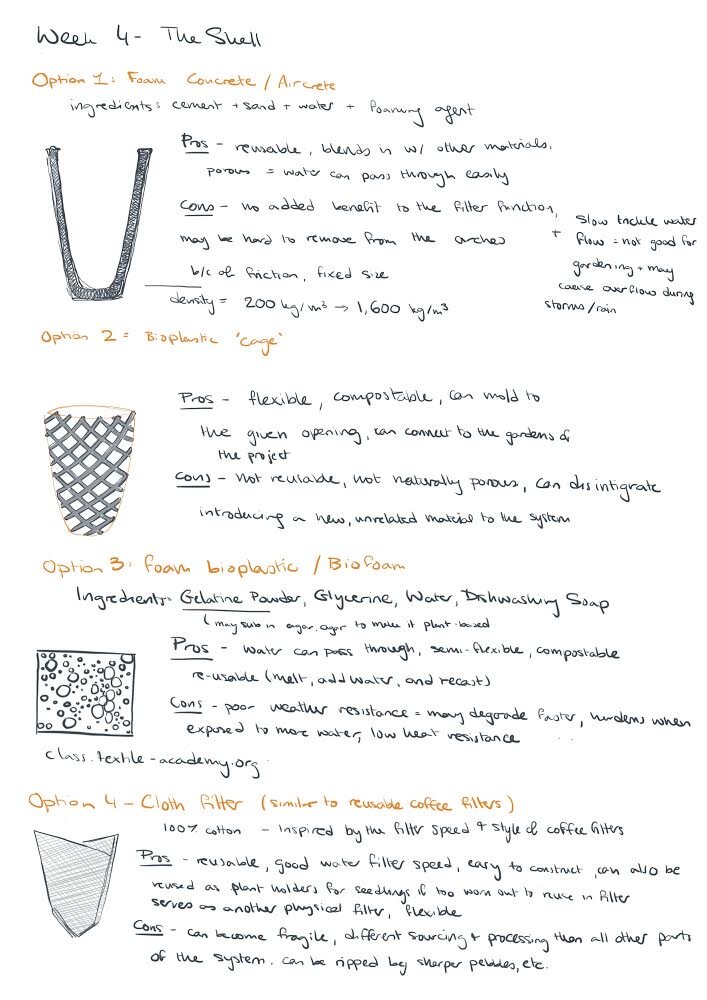

FILTER SYSTEM

This filter system was designed to combat the historic and systemic misuse of the site as an illegal dumping ground. Since this ground was on a steep decline down to the river, the filter was designed to process rain and ground water runoff and reduce soil toxicity.

By incorporating activated charcoal into the cement ‘pebble’ system, the filter works as both a physical and a chemical filter to function at a macro and micro scale. The filter is designed to fit the material and formal language of the overall architecture and the architecture was also iterated upon to further support the filtering function, leading to a symbiotic system that draws inspiration from the area but also actively works to benefit the health of the neighborhood in program and form.

Long Section Perspective - Geothermal wells and soil filters round out the program

The project is designed to be formed from large scale 3D printing of a cement and local soil aggregate. Since the aqueduct shape repeats across the site and the house forms are identical to one another, most of the 3D printing could potentially be stream lined and made off-site to reduce the destruction that could occur from construction on site. The repeating forms also mean that the digital processes to create the design are also more energy efficient in manufacturing and construction.